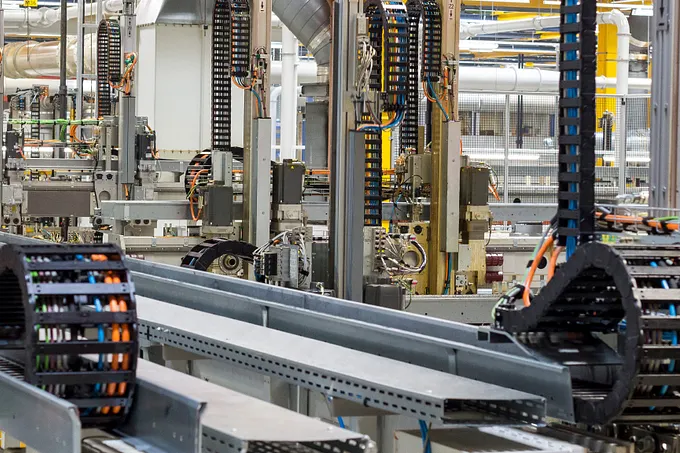

The management of moving cables and hoses in machine building is critical to the operation and longevity of the equipment with modern systems like energy chain cable carriers often replacing conventional systems like cable festoons, reels or free-hanging loops.

Introduced in South Africa by German polymer manufacturer, igus, the innovative polymer chains act as a protective guide for cables and hoses, ensuring that they move in a defined, controlled path without tangling, twisting or wearing prematurely.

Widely used in manufacturing, automation, packaging, mining, robotics and machine tool industries, igus energy chains are fast replacing traditional festoon and cable reel systems due to their low-maintenance characteristics and ability to handle multiple energy types (electrical, hydraulic, pneumatic, fibre optic and even auxiliary components such as hoses) all in one neat, flexible solution.

“Our e-chain cable carriers are increasingly being designed into new systems or retrofitting festoons and cable-reel systems in most industries. Our e-chains simply act as a moving conduit or a sort of spine that keeps the cable neat and always protected,” says igus South Africa managing director, Ian Hewat.

According to him the following are the ten most compelling reasons why engineers and system integrators in South Africa are increasingly turning to igus energy chains when designing and building machines:

- Cable-friendly design

igus energy chains have smooth inner surfaces and controlled minimum bending radius based on cable specification. It also protects cables and hoses from micro-abrasions and stress cracks. This drastically reduces premature failures and extends cable life even in highly dynamic applications.

- Modular, lightweight and strong

Made from high-performance polymers, igus chains are lighter than metal systems yet offer impressive strength and stability. Their modular construction means they can be easily extended, shortened or customised on site which makes them ideal for tight project timelines.

- Multi-media integration

Igus energy chains can simultaneously carry electric cables, pneumatic lines, hydraulic hoses and even fibre optic cables in a coordinated and well protected housing. This helps streamline machine design and reduces the number of separate systems required.

- Predictable service life with warranty

igus backs its products with a guaranteed service life based on millions of lab-tested cycles. Many igus chainflex cables carry up to a four-year warranty or the prescribed minimum cycles lifespan, offering peace of mind to OEMs and machine users alike.

- Low-friction, energy-efficient operation

igus chains glide with minimal resistance thanks to their self-lubricating plastic design which significantly reduces drag forces. This makes them more efficient than festoon or reel systems that suffer from mechanical resistance or cable overlap.

- Maintenance-free operation

No greasing or lubrication is needed throughout the life of the chain. This reduces downtime and makes igus energy chains perfect for use in clean environments like food processing or high-dust areas like cement and mining operations.

- Quick configuration and customisation

Designers can use the free igus online configurators to select, model and download their ideal energy chain setup. This speeds up the design process and ensures perfect compatibility with machine layout.

- Intelligent condition monitoring

With igus’s i.Sense smart plastics add-on sensors can be embedded to monitor wear, cable tension and chain motion in real-time. This enables predictive maintenance and reduces the risk of cable failure.

- Space-saving and safe

Energy chains allow for neatly routed cables and hoses that don’t hang or swing in order to improve machine aesthetics and workplace safety. They also fit into compact machine designs where festoons or loops would be impractical.

- Broad industry uptake

igus e-chains are in use in over 50 industries from CNC machines and robotics to packaging lines, quarries and marine applications. Their proven versatility makes them a reliable choice across virtually any moving cable application. From travels as short as 100mm up to the current longest application of 950m.

Ian Hewat

igus South Africa

Tel. +27 11 312 1848

ihewat@igus.de

www.igus.co.za