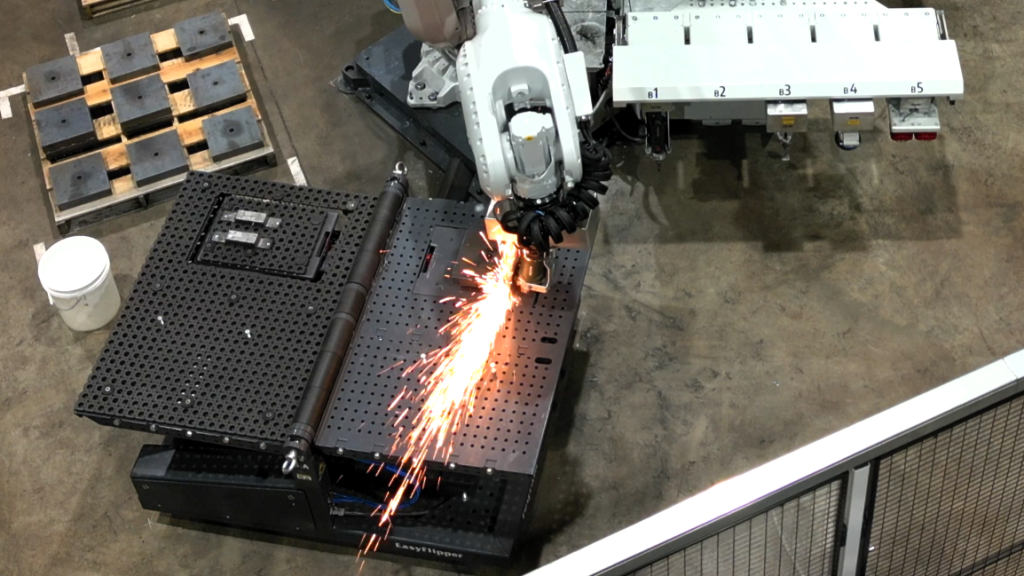

Thanks to the EasyGrinder, Minerd & Sons reduced lead time from two weeks to just three days – a breakthrough in productivity and delivery reliability. The leading regional steel service center in Pittsburgh, Pennsylvania, has fundamentally accelerated the finishing of plasma- and oxy-fuel–cut plate parts with the implementation of the EasyGrinder, Teqram’s autonomous grinding robot. The system processes heavy plates fully automatically, without programming or teaching, and delivers consistent quality with a significantly higher throughput.

Raising the Bar on Service and Edge Quality

As a key supplier to manufacturing, construction, and heavy equipment customers, Minerd & Sons processes thousands of tons of steel plate annually. The final quality of thermally cut edges directly impacts weldability and coating performance. Until recently, cleaning and finishing these edges was a highly physical manual task performed by skilled workers. “We’ve always invested in the best technology to serve our customers,” says Mark Minerd, President of Minerd & Sons. “Delivering ready-to-fabricate components requires perfect edge preparation, and manual grinding had become a bottleneck.”

Automation Solves Labour, Safety, and Consistency Challenges

The EasyGrinder now performs this critical finishing step across a wide range of part geometries, boosting throughput while addressing labour market pressures. “We wanted to free our skilled people from repetitive, exhausting work and let them focus on higher-value tasks,” Mark explains.

“It is a huge win for safety and the long-term well-being of our team.”

He continues, “And beyond that, the system delivers perfectly repeatable quality on every part. It gives our customers a level of consistency that would be nearly impossible to achieve by hand.”

Proven Technology, Confident Investment

A thorough evaluation process built trust in the EasyGrinder’s reliability. “We were concerned about needing to supervise the system constantly,” says Matt Minerd, Work Order Manager. “Teqram showed us the EasyGrinder was a mature, production-proven product. Their team delivered innovative solutions for our toughest parts. Their philosophy is truly outstanding.” The benefits were immediate. “Unlike flatbed grinding machines, the EasyGrinder handles both internal and external leads with ease,” Matt notes.

Smart, Flexible Edge Preparation

The EasyGrinder is not a fixed, conventional automation system but a smart and flexible solution that uses advanced 3D vision technology and an AI-based controller to recognize each component’s geometry and automatically select the correct processing strategy. It removes heavy slag with ease, softens sharp edges, and can precisely round profiles – such as creating a consistent two-millimeter radius – to ensure optimal coating adhesion. At the same time, it cleans and removes the heat-affected zone from the cut surfaces, leaving parts truly production-ready. Employees only need to place pallets of raw parts in the work area; from there, the robot handles, processes, and neatly restacks every component without further intervention.

“Parts come off the robot ready to ship – no extra finishing needed.”

Maximum Uptime and Exceptional Support

To increase throughput and reduce lead times, Minerd & Sons schedules large batches for unattended overnight production. Mark emphasizes:

“Lights-out grinding adds the equivalent of an extra shift without adding staff”

The collaboration with the Netherlands-based Teqram has been equally impactful. “The time difference works in our favour,” Matt says. “We report an issue during the day, and by the next morning Teqram already has a solution. Their direct service and detailed video logs show they truly care.”

Next Level Performance

With the EasyGrinder, Minerd & Sons strengthens its position as an industry leader – delivering consistent quality, safeguarding employees, and maximizing operational efficiency.

“Thanks to the EasyGrinder, our lead time has dropped from two weeks to only three days. This improvement gives us the confidence to accept bigger projects.”

Minerd & Sons, Inc.: Precision Steel Processing with a Legacy of Service

Minerd & Sons, Inc. is a family-owned steel service center based in Pittsburgh, PA, supplying high-quality plate processing to customers in manufacturing, construction, energy, and heavy equipment industries. With decades of expertise and a strong commitment to service, the company delivers precision-cut, ready-to-fabricate steel components backed by operational excellence.

Simplifying Industrial Automation with Intelligent Robotics

Teqram is a Netherlands-based developer of advanced autonomous robotic systems designed to simplify and modernize industrial production. With a strong focus on ease of use, flexibility, and reliability, Teqram delivers plug-and-produce solutions that require no robot programming or teaching. Their systems combine intelligent 3D vision, powerful AI-based software, and robust mechanical engineering to automate labour-intensive processes such as grinding, deburring, and material handling. Teqram enables production companies to boost efficiency, reliability, and workforce wellbeing through smart, accessible automation.

Expanding Autonomous Sheet Metal Automation in North America

Teqram has contracted with Automated Fabrication Systems (AFS) in Carson City, Nevada, to develop the North American market for its solutions. With over 25 years of experience in advanced sheet metal processing technologies, AFS delivers state-of-the-art systems that improve productivity, reduce material costs, and enhance quality. Supported by time studies, integrated solutions, and comprehensive training and service, AFS enables manufacturers to adopt automation faster and achieve a strong return on investment.

Learn more at minerdandsons.com, automatedfabricationsystems.com and teqram.com.