Manualpost-processing of flame-cut and plasma-cut parts is still seen as a necessary but inefficient task in many companies. Removing slag, breaking edges, grinding radii – all physically demanding, noisy, and difficult to reproduce consistently. As quality demands increased, LISEGA realised that this process needed a technological leap. The company found its solution in Teqram’s EasyGrinder.

When automation became essential

As a specialist in industrial pipe support systems, LISEGA offers a modular product range with tens of thousands of standardised items. At LISEGA, post-processing of sheet-metal blanks involved several manual steps that required significant time and skilled labour. Growing product variation made it increasingly difficult to maintain consistent quality. “We were very pleased to find a market-ready, standardised automation solution for this,” says Michael Witten, Deputy Head of Production Technologies. The key advantage was the ability to automate the entire workflow in one seamless sequence:

“Integrating the entire deburring process into one operation and letting the EasyGrinder take over was the winning formula.”

Robotics without programming

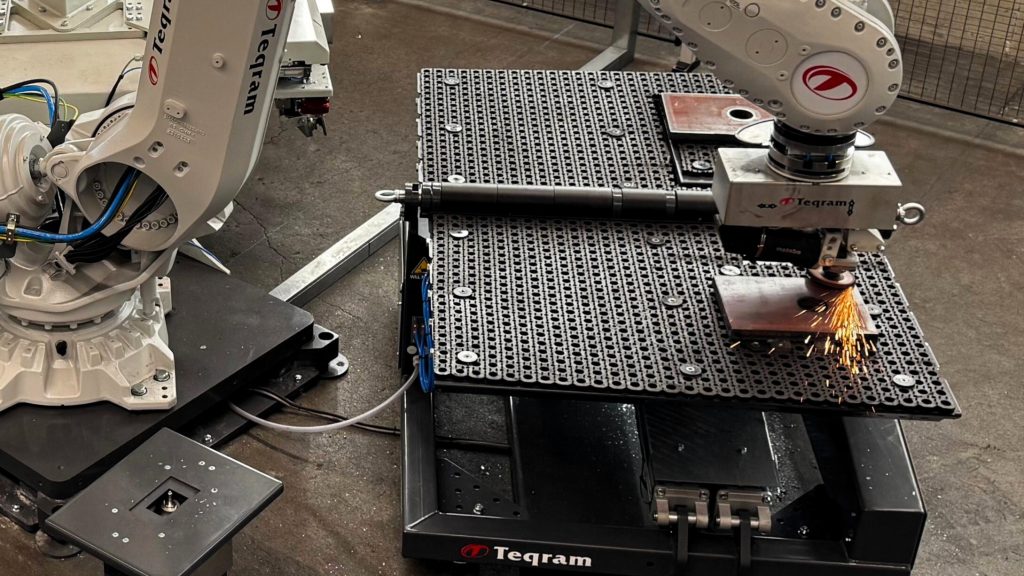

It quickly became clear that a conventional robot system requiring complex individual programming would not be economical for LISEGA. Teqram’s EasyGrinder solves this challenge with AI-driven vision technology. The robot identifies each workpiece, analyses its geometry, and selects the appropriate tools and grippers independently. The operator only needs to define the desired quality outcome. Witten emphasizes:

“The Teqram EasyGrinder can handle all steps, from slag removal and edge chamfering to removing lead-in burrs and grinding to a radius of R2.”

Consistent quality and real relief for employees

The EasyGrinder replaces multiple manual steps with an automated process that is fast, safe, and highly reproducible. Throughput times are significantly reduced, while quality remains consistently high – regardless of the component’s complexity. At the same time, employees are relieved from heavy, repetitive grinding work and can focus on higher-value tasks. A system that improves over time LISEGA particularly values the continuous development of the EasyGrinder software. New functions such as chamfering and marking are added via updates.

Witten explains: “It’s rare to buy a system that becomes more efficient over time.”

More speed, more quality and more future-proof

The EasyGrinder demonstrates how modern robotics delivers real added value: faster processes, repeatable quality, and significantly reduced physical strain. For LISEGA, automated deburring has become not only more efficient but also strategically future-oriented – clear proof that robot-assisted processes can now be used productively without any programming effort.

LISEGA: Leader in a Global Niche Market

LISEGA SE, headquartered in Zeven, Germany, is a leading global supplier of modular pipe support systems for energy plants, petrochemical facilities, and the process industry. The company employs around 1,000 people in seven production sites, and offers the world’s most comprehensive range of standardised pipe support components.

Teqram: Robotics Without Programming

Teqram is a Dutch technology company specializing in robot-assisted automation solutions that require no programming. With a strong focus on AI, vision technology, and intuitive operation, Teqram develops solutions for the sheet-metal industry that fully automate complex and physically demanding workflows.