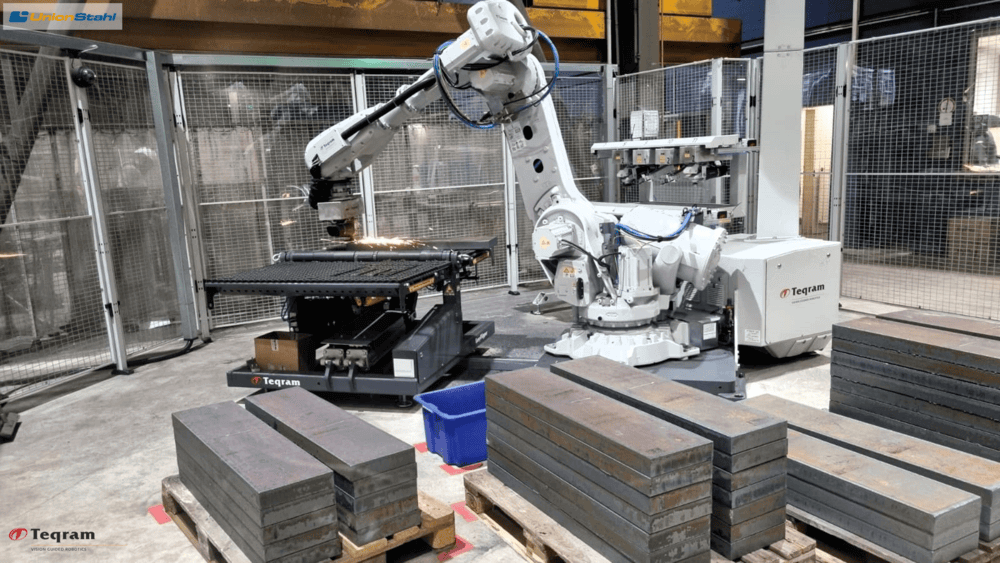

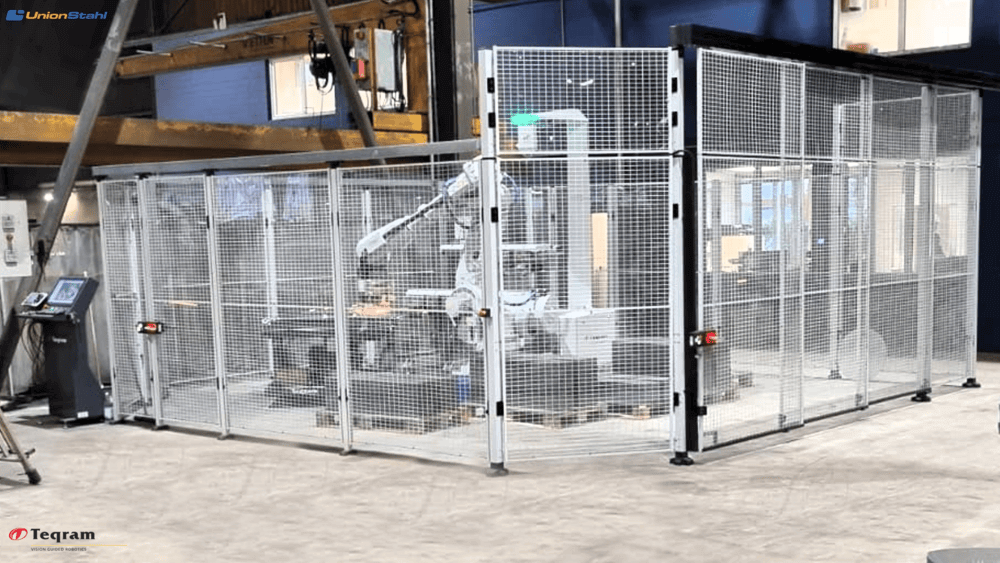

UnionStahl, one of Europe’s leading steel traders and flame-cutting companies, has taken another step in its automation strategy. Flame-cut parts are now cleaned fully automatically – without programming – using the EasyGrinder from Teqram. This innovation reduces physically demanding work, increases processing quality, and enhances efficiency across production.

Maximum efficiency in large-scale production

With an inventory of 60,000 tons and an annual processing capacity in the four-digit ton range, UnionStahl generates thousands of flame-cut and plasma parts daily. Cleaning these components before shipment or further processing is essential. A significant portion of this work is now performed automatically – quickly, reliably, and without manual programming.

Longstanding automation partnership

UnionStahl implemented the first automation solutions from Teqram six years ago. Since then, two continuous deburring systems from ARKU have been loaded and unloaded automatically with the Teqram EasyDebur systems. Subsidiaries also rely on Teqram technology, for example, for unmanned, double-sided shotblasting of thermally cut components.

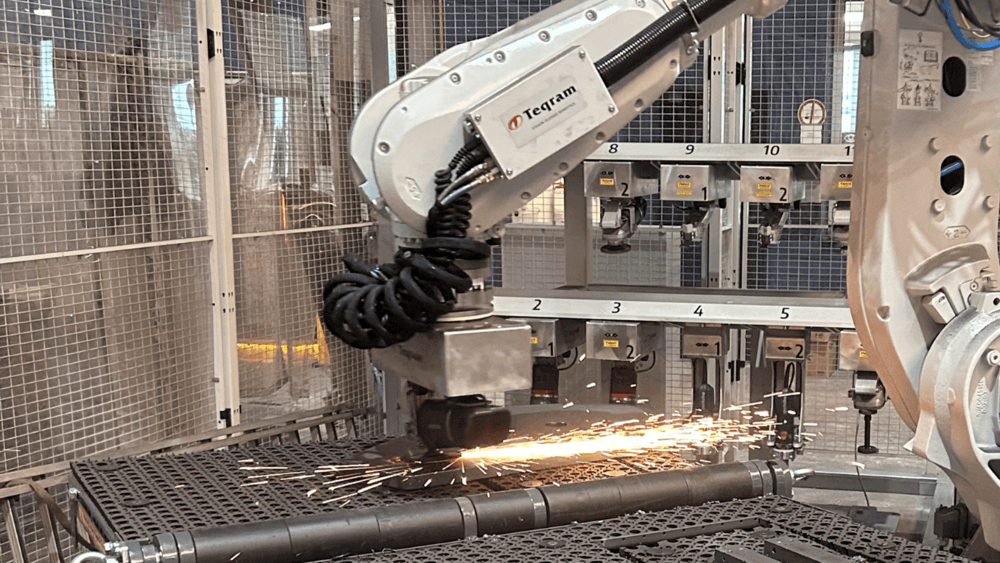

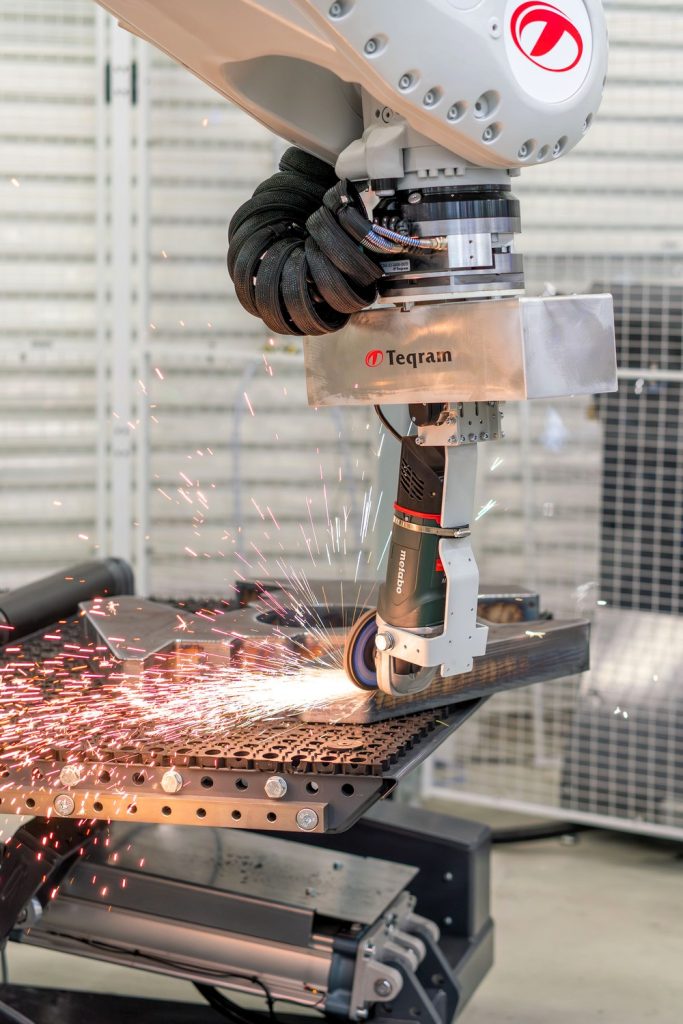

EasyGrinder – Precise post-processing for complex requirements

Since early 2025, the EasyGrinder in Duisburg has complemented the deslagging and grinding process. The robot takes over the finishing of components where conventional continuous systems reach their limits – for example, when removing starting points, grinding hardened cutting edges, or applying chamfers.

Multiple work steps combined in a single process

The EasyGrinder reduces physically strenuous activities such as manually lifting and moving heavy parts. Furthermore, several processing steps can be combined in one automated process: slag removal, deburring, grinding, marking, countersinking, chamfering – even shotblasting can be integrated. This eliminates the need to handle parts multiple times, and manual rework is virtually unnecessary.

Solving bottlenecks and supporting skilled workers

Recruiting and retaining skilled workers for manual finishing remains difficult. A fluctuation in the post-processing capacity often leads to production delays. The EasyGrinder addresses this by ensuring predictable workflows while enabling skilled employees to focus on higher-value tasks.

Continuous innovation through the Teqram community

Ulrich Stumpf, Head of Flame Cutting at UnionStahl, emphasizes the value of Teqram’s customer network:

“All customers benefit from every new development, as the software and its functionality are continuously expanded.”

Functions such as marking or chamfering, not available five years ago, are now standard thanks to regular software updates. Additional tools can be retrofitted as needed, ensuring the system evolves with customer requirements.

Proven investment and outstanding service

After six months of operation, UnionStahl confirms the EasyGrinder has delivered clear benefits. Just as important, Teqram’s service has impressed:

“The service is simply outstanding – you rarely find something like that,”

says Ulrich Stumpf. Teqram solutions are already successfully deployed at several locations and are considered an integral part of modern machining processes.

Technology drives competitiveness

By introducing the EasyGrinder, UnionStahl reaffirms its strategy of consistent automation in steel processing. In an environment of skilled labour shortages and cost pressure, intelligent robotics from Teqram provide sustainable advantages for modern industrial companies.

About UnionStahl

UnionStahl is one of Europe’s leading suppliers of heavy plate. In addition to an extensive stock program, the company provides customized processing solutions. Based in Duisburg and with subsidiaries across Europe, UnionStahl serves demanding customers in mechanical engineering, plant construction, offshore, and steel construction.

Teqram: Smarter fabrication through vision-guided robotics

Teqram is committed to transforming metal processing with AI enhanced robotic systems that simplify automation. Their vision technology eliminates the need for programming, making the systems very easy to operate.

Learn more at unionstahl.com and teqram.com.