Established in 1995 and a part of the Techno Group, Technoturn is a leading precision engineering company based in St. Leonards-on-Sea and specialising in high-precision machined components and assemblies.

The company serves critical industries including aerospace, defence, motorsport, laser technology, telecommunications, and opto-electronics.

Equipped with state-of-the-art CNC sliding-head and fixed-head lathes, alongside multi-axis milling centres, Technoturn offers turning capabilities ranging from 1mm to 200mm in diameter.

The company prides itself on its flexibility and collaborative approach, supporting research and development projects by transforming conceptual designs into finished, high-quality components. It provides comprehensive traceability, scheduled deliveries, and flexible batch production, while also managing essential secondary operations such as grinding, heat treatment, and plating. Holding AS9100 certification since 2008, Technoturn adheres to stringent quality standards, solidifying its reputation as a trusted supplier for high-tech sectors.

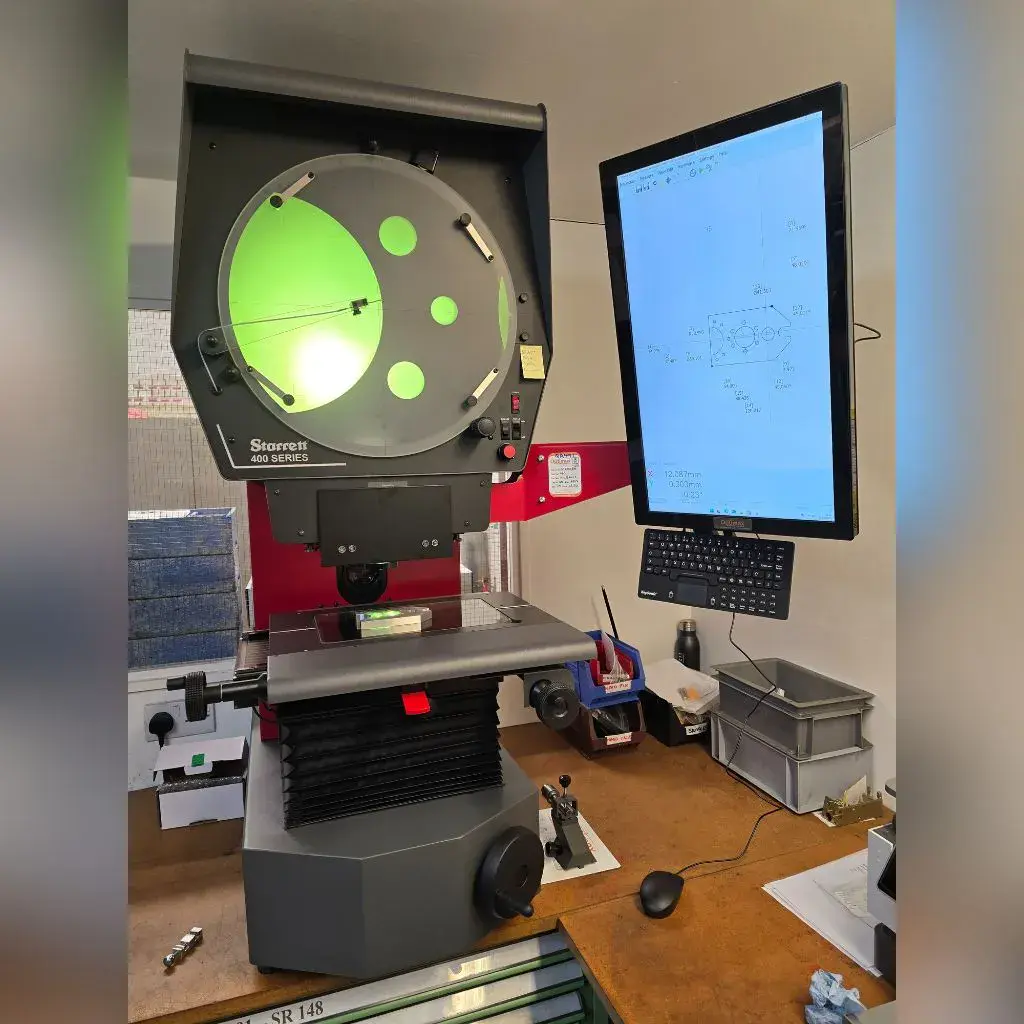

Recognising the need to enhance efficiency, increase output volume, and maintain the highest level of quality assurance, Technoturn sought an advanced vision inspection solution. The Starrett VB400 with Synergy software was selected from Optimax to meet these demanding requirements and support its ambitious growth plans.

Technoturn’s previous inspection system, a manually operated profile projector, no longer met the increasing accuracy demands of its customers and lacked the necessary reporting capabilities. The implementation of the Starrett VB400, equipped with Synergy PC-based software, provided a significant upgrade.

The Synergy software delivers powerful metrology functionality, enabling rapid measurement of complex geometries through optical profiling. Key features include comprehensive reporting for internal use and customer communication, enhanced networking for seamless data sharing and integration, integrated statistical process control (SPC) for real-time monitoring and analysis, GD&T functionality for precise geometric dimensioning and tolerancing, CAD comparison and reverse engineering for streamlined design verification, and an optical edge probe facilitating rapid measurement of complex and freeform geometries, reducing operator error and enhancing ease of use.

Ian Lloyd, quality manager, at Technoturn says: “The VB400 enhances our inspection capabilities with the addition of reporting and programming comparable to our current CMM.”

The VB400 stood out as a choice for Technoturn due to several key advantages over its previous system. The vision system’s robust design and the Synergy software, similar to existing software in use on its CMM, allowed for seamless integration and minimal operator retraining. Additionally, the standard LED lighting and precision lens provided high contrast for accurate measurement of surface, edge, and blind hole features.

The VB400’s professional reporting outputs enable the creation and export of customised templates, saving time and ensuring accuracy in customer communication. To ensure compliance with international standards, the equipment is UKAS calibrated by Optimax, providing independent verification and well-defined measurement uncertainty. This calibration process reinforces Technoturn’s commitment to quality and precision.

Mr Lloyd adds: “The VB400 is transformative – optimising processes and reducing inspection times – and with the addition of reporting and programming comparable to our current CMM. With Optimax’s UKAS accredited service and calibration support I’m confident that the VB400 will continue to optimise our inspection process.”

He continues: “From start to finish, Optimax provided excellent service. Dan Allen, the engineer, was professional, efficient, and highly knowledgeable throughout the installation, calibration, and training process. The Synergy software closely mirrored our CMM software, ensuring a smooth transition to programming routines and generating reports, and significantly reducing implementation time. Given this experience, we will certainly consider Optimax for future inspection requirements and system upgrades, including enhancements to our vision system.”

Optimax

www.optimaxonline.com