Efficiency and safety are crucial in sheet metal manufacturing. At WBM, a dutch expert in high-strength and wear-resistant steel fabrication, one particular challenge had been on the radar for some time: flipping large cut parts quickly and safely. With the introduction of the EasyFlipper from Teqram, that challenge has now been smartly resolved.

Complex Products Require Smart Solutions

WBM, based in Stramproy (Netherlands), specializes in the production of complex components made from steel plate. The company focuses on high-strength and wear-resistant steels with thicknesses ranging from 4 to 40 mm. Its production floor houses a modern machine park, including two fiber lasers, a plasma cutting system, 3D lasers, and press brakes with capacities up to 1,000 tons and lengths of up to 6 meters.

Manual Flipping of Heavy Plate Parts

WBM had long been looking for a solution to flip heavy plasma-cut parts safely and quickly. These components are often 30 to 40 mm thick and quite large in size. For deburring and countersinking, flipping is essential. Until recently, this was done using a sling or magnet on the overhead crane – a method that involves safety risks and puts considerable physical strain on operators.

Flipping at the Deburring Machine

For lighter components, WBM uses a deburring machine that processes only one side of the material. To remove burrs or slag from the underside, those products must also be turned over. This process was particularly difficult for long, thinner parts – they tend to flex and behave unpredictably during handling. As a result, at least two operators were needed, and it was hard to position a magnet or sling in a way that ensured safe and stable flipping.

Sound Advice

A major new order involving long sheet parts prompted WBM to actively search again for a safe and efficient handling solution. Online, WBM soon came across the EasyFlipper from Teqram.

“During our visit to the Teqram demo centre in Zwolle, not only was the EasyFlipper demonstration convincing, but the tour of their autonomous robotic systems was equally impressive”

says Hans Besseling, Managing Director at WBM. “There was no sales pitch – just well-founded advice on the best configuration for our application. We visited on Friday and placed the order on Monday. This is one of those purchases where you don’t need to run the numbers – you just know it’s the right decision.” Because Teqram manufactures the EasyFlipper to stock, the machine was available immediately, including extension arms for supporting long plates.

Installation is Easy

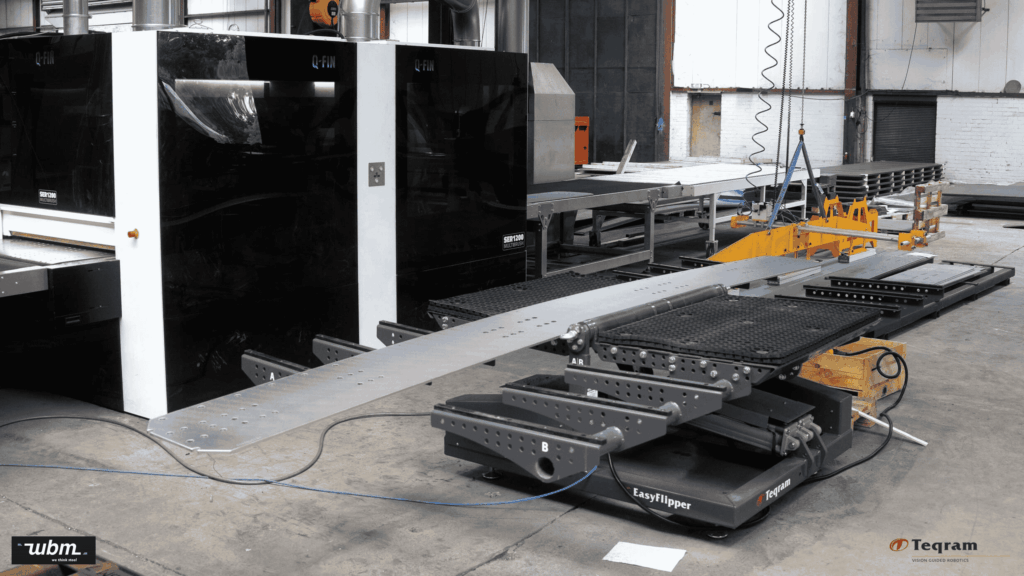

Installation of the EasyFlipper was handled by WBM’s own technical team. “It’s really simple,” Besseling explains. “You place the machine, plug it in, connect the compressed air – and that’s it. Since the EasyFlipper is mobile and can be moved with a forklift, we can deploy it flexibly at the plasma cutting station, the press brake, or the deburring machine – wherever it delivers the most value at the time.”

RELATED: Robotic Grinding for Surface Preparation Level P3:

Robust Design

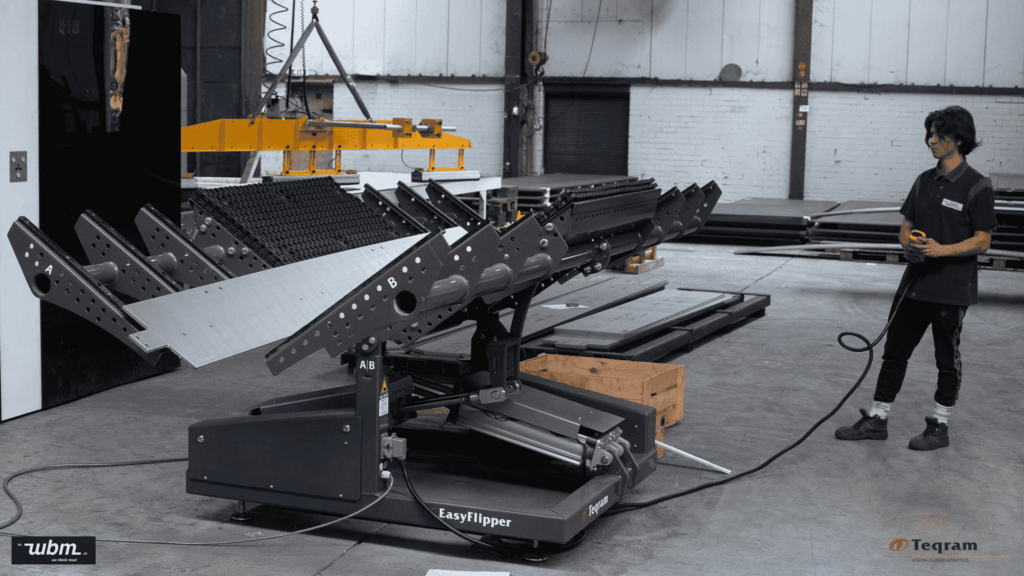

In daily use at WBM, multiple long parts are often loaded onto the EasyFlipper and flipped simultaneously. “That was a bit of a shock the first time,” Besseling admits. “The plates swing dramatically during the fast tilting action. But after a few tries, you realize: this works perfectly. The construction is simple yet smart, and the use of high-quality components really appeals to me as a technician. This machine is built for heavy industrial use.”

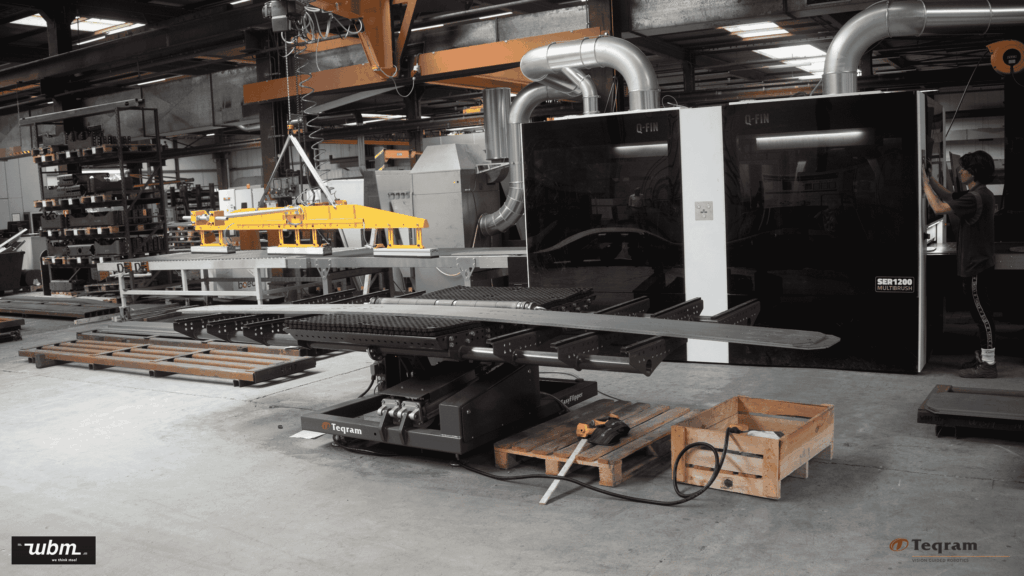

Flexible Deployment

The EasyFlipper was initially positioned next to the plasma cutting machine. There, the operator can deburr and countersink parts immediately during cutting, and independently flip heavy components. It is now also used at the new Q-Fin deburring machine. For a new project, long parts need to be rounded on all sides with a 2 mm radius after laser cutting. To meet this requirement, WBM replaced its old deburring machine with a new Q-Fin. Parts are moved from the large laser cutting machine to the infeed conveyor of the Q-Fin. On the outfeed side, they are stacked onto the EasyFlipper using a wall-mounted crane. The machine helps the operator quickly and safely flip the parts, which then re-enter the Q-Fin for underside processing.

Fast, Safe, and Ergonomic

“We haven’t done any formal timing yet, but the EasyFlipper is clearly faster than flipping with a sling or magnet on a crane,” Besseling says. “Especially because we flip up to four large plates of 170 kg at once. The EasyFlipper supports our core processes – it might be idle most of the time, but when we need it, it works instantly and ensures that the deburring process doesn’t slow down. And just as important as the time savings is the improvement in safety and ergonomics. There’s no longer any risk of unsafe situations. Even long, flexible plates that were previously difficult to flip can now be handled effortlessly by a single operator.”

A Valuable Asset for Heavy Plate Handling

For technical companies working with large or heavy sheet metal parts, the EasyFlipper is a highly valuable addition to the machinery lineup. Its combination of robust construction, ergonomic design, and smart functionality makes it an ideal solution for improving both safety and productivity in demanding production environments. More information is available at www.teqram.com.