The EasyGrinder Revolutionizes Steel Construction

In the world of steel construction, surface preparation is more than a preliminary step—it’s a defining factor in durability and corrosion resistance. While removing slag and burrs is routine, achieving a consistent edge radius of at least 2 millimetre remains a labour-intensive challenge. Traditionally, this process requires skill, endurance, and time. Now, the Teqram EasyGrinder is changing the game, offering an autonomous solution that simplifies deslagging and grinding and seamlessly integrates with automated shot blasting.

Automation Meets Adaptability

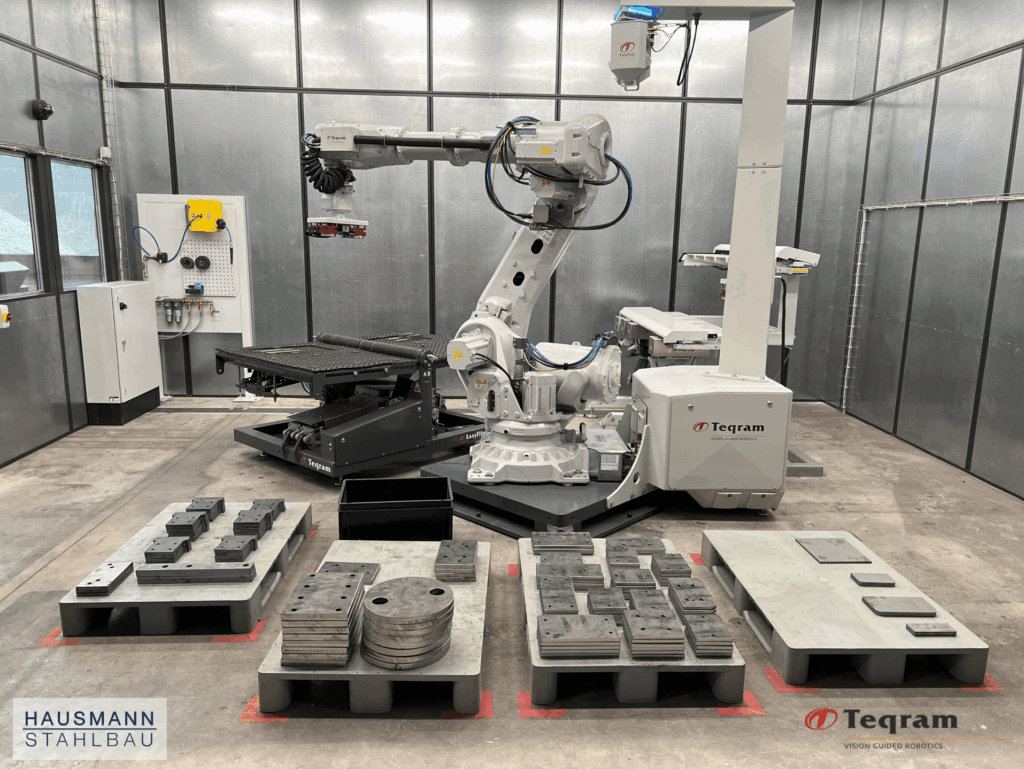

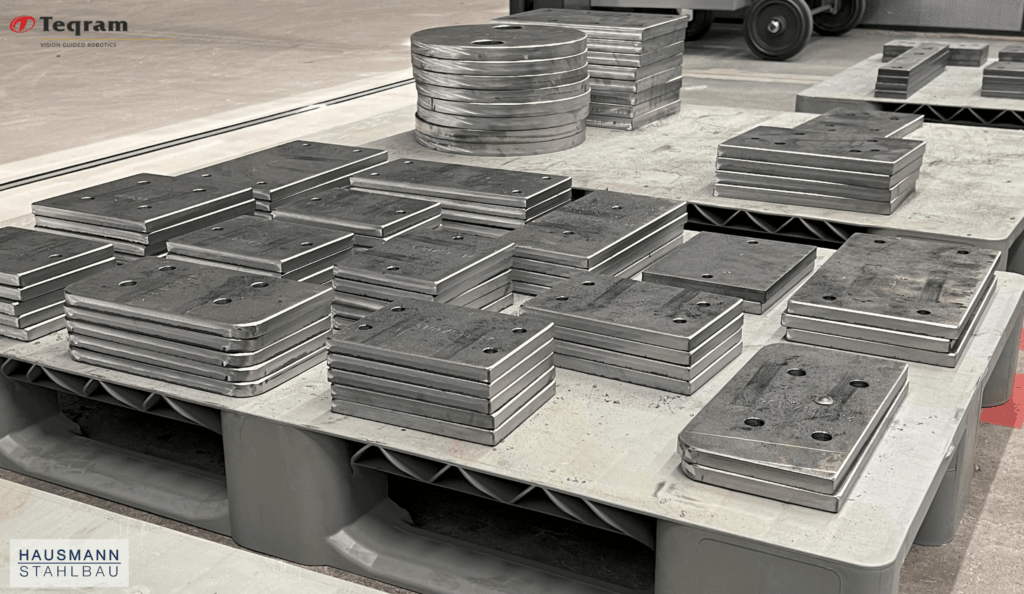

Equipped with advanced 3D vision and an AI-driven controller, the EasyGrinder processes thermally cut steel workpieces without requiring programming or preloaded geometry data. This capability makes it an ideal solution for steel construction firms that frequently work with custom designs or small production runs. By adapting on the fly to different workpieces, the system ensures a level of precision and efficiency that manual methods struggle to match.

A Versatile Approach to Grinding

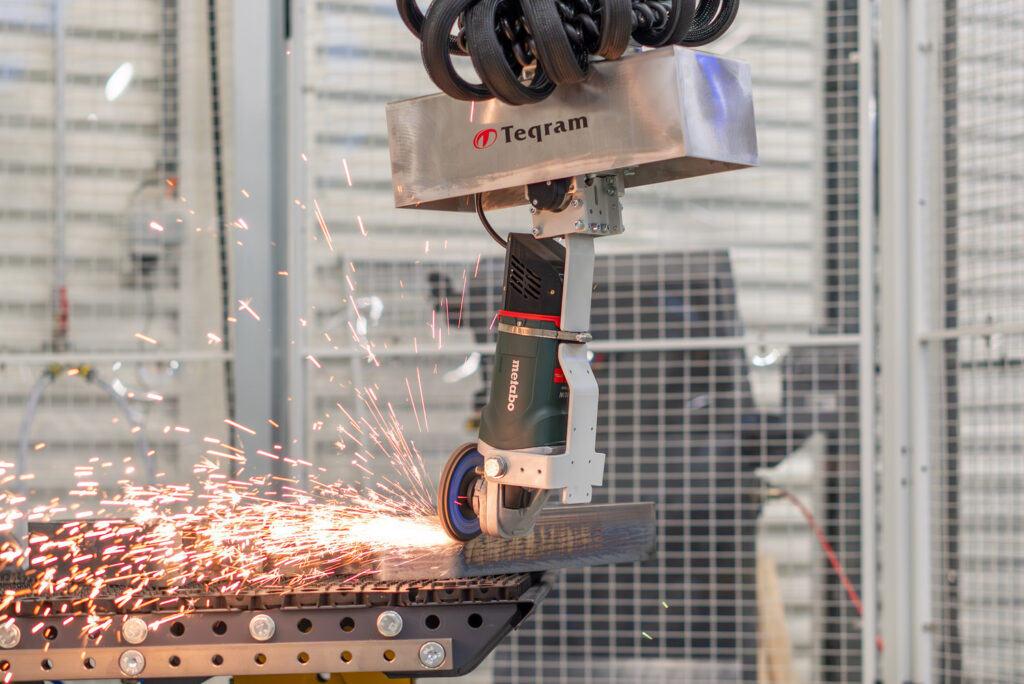

What sets the EasyGrinder apart is its flexible tooling system, which adjusts to the specific needs of each component. Slag removal is handled with a chisel, while edge rounding is achieved using a lamella disc or a pencil grinder, depending on the shape of the workpiece. For cutting edges, an angle grinder is used, while countersinking tools refine drilled holes. Even intricate lead-ins or starting points are efficiently removed. This adaptability guarantees optimal surface preparation, regardless of complexity.

No Programming, No Hassle

One of the standout features of the EasyGrinder is its ability to operate without programming or preloaded geometry data. Using real-time 3D vision, the system detects the geometry of each workpiece and determines the best processing strategy. For instance, when creating a 2 millimetre radius, the system performs the operation in three controlled steps with a flap disc, ensuring compliance with the specifications of Part 4 of ZTV-ING for the implementation of DIN EN 1090-2. The operator’s role is simple: place the workpieces on pallets within the robot cell and select the desired processing quality from pre-set options.

Why Surface Preparation Matters

Strict standards such as DIN EN ISO 8501-3 and DIN EN ISO 12944-2 define the levels of surface preparation required for effective corrosion protection. These standards, in conjunction with DIN EN ISO 1090-2, emphasize that proper surface treatment directly affects the durability of protective coatings. By adhering to the classification of corrosivity categories and durability considerations outlined in DIN EN ISO 12944-2, steel structures gain enhanced resistance to harsh environmental conditions, ensuring long-term performance and structural integrity.

Seamless Integration with Shot Blasting

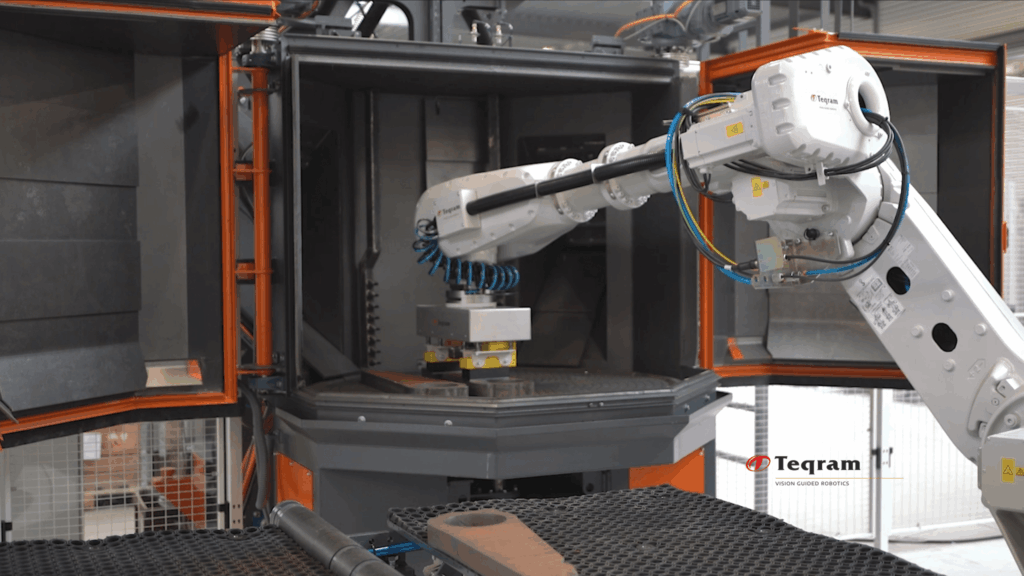

Efficiency in steel fabrication doesn’t end with grinding. The EasyGrinder is designed to work in tandem with automated shot blasting systems, streamlining the entire surface preparation workflow. Once the grinding process is complete, the robot places workpieces into a rotary table shot blasting machine, where both sides are treated. Thanks to an automated turning system, manual intervention is minimized, while double-blasted edges improve coating adhesion and eliminate shadowing effects. Additionally, rotary table shot blasting consumes significantly less energy than traditional roller conveyor systems, leading to substantial cost savings.

RELATED: EasyGrinder Boosts Production at Amtenbrink and Replaces Three Temporary Workers

Addressing the Skilled Labor Shortage

The steel industry, like many others, faces an increasing shortage of skilled workers. Manual grinding and blasting are not only physically demanding but also prone to inconsistencies. By automating these labour-intensive tasks, the EasyGrinder allows experienced professionals to focus on higher-value work, while ensuring reliable, repeatable quality in surface preparation.

Redefining Efficiency in Steel Fabrication

With its combination of precision, adaptability, and ease of use, the EasyGrinder represents a significant leap forward in steel processing. By reducing reliance on manual labour, enhancing consistency, and integrating seamlessly into existing workflows, it offers a smarter, more efficient way to meet the demands of modern fabrication. In an era where automation is reshaping industries, Teqram’s EasyGrinder stands at the forefront, proving that the future of steel construction is not just automated—but optimized.