Hydrogen has been a staple in industrial applications for over a century, known as the lightest gas with unique physical and chemical properties. While hydrogen’s flammability range in air is broader than most common fuels (4% to 75% at room temperature and pressure), extensive practice has shown that it can be a relatively safe energy carrier when safety protocols are strictly followed.

I. Safety Advantages

- Rapid Diffusion: Due to its low density, hydrogen disperses quickly, rapidly diluting to non-combustible concentrations in open spaces.

- Non-Toxic: Hydrogen itself is non-toxic, and its combustion produces mainly water, without harmful gases.

- Low Explosion Energy: The energy released from explosions per unit volume is relatively low, minimizing potential hazards.

II. Safety Management Strategies

- Leak Detection: Exploiting hydrogen’s high diffusivity, detection devices are typically installed at the upper levels of enclosed spaces.

- Ventilation Design: Ensuring adequate ventilation is crucial to prevent H accumulation.

- Material Selection: To prevent hydrogen embrittlement—a phenomenon where metals become brittle due to hydrogen infiltration—appropriate materials are selected. Preventive measures include using hydrogen-resistant materials and barrier coatings.

- Safety Systems: Fuel cell systems are designed with comprehensive monitoring and shutdown mechanisms to enhance safety.

III. Safe Practices in H Applications

1. Storage: Modern storage tanks undergo rigorous safety testing, including fire and ballistics tests, ensuring high safety standards.

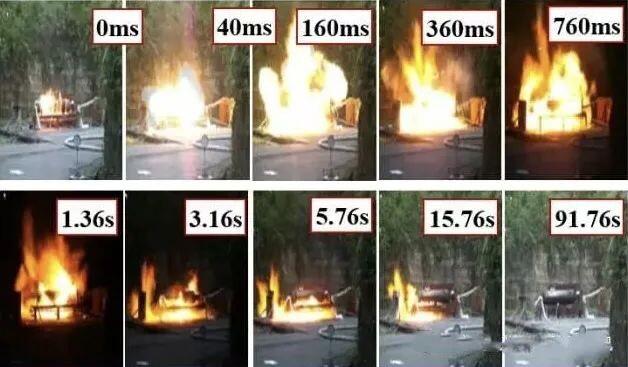

Fire Test: When hydrogen tanks are exposed to fire, the flames peak during the first second and then rapidly diminish, extinguishing after 5-15 seconds. Notably, even under direct fire, the tanks do not explode.

- Ballistic Test: In a test where a 35 MPa tank was pierced by a bullet, it was observed that no explosion occurred. The hydrogen escaped rapidly upwards, and the entire tank was depressurized through a single bullet hole within 45 seconds.

2. Fuel Cell Systems: Fuel cell systems are designed to separate the storage tank from the power generation system, reducing safety risks. These systems are equipped with advanced safety features, including over-temperature and over-pressure protection, as well as continuous monitoring.

Conclusion

While hydrogen does pose certain risks, these can be effectively managed through a scientific understanding of the gas, comprehensive safety management systems, and strict operational procedures. With technological advancements and improved safety protocols, it is poised to become a key component in the future of clean energy systems.

Source: Sany Insights