Beckhoff Automation. In today’s fast-paced industrial landscape, automation is key to maintaining competitiveness and efficiency. The tire and rubber industry, a cornerstone of the global manufacturing sector, is no exception. Beckhoff, a leader in automation technology, offers innovative solutions that significantly enhance production processes. Let’s briefly look at Beckhoff’s contributions, showcasing how their automation systems optimize operations in the tire and rubber industry.

The Role of Automation in the Tire and Rubber Industry

Automation is transforming the tire and rubber industry by streamlining production, improving quality, and reducing costs. From material handling to final inspection, automated systems ensure precision and consistency. Beckhoff’s advanced automation solutions are at the forefront of this transformation.

Beckhoff’s Advanced Automation Solutions

Integrated Control Systems

Beckhoff’s integrated control systems provide a unified platform for managing complex manufacturing processes. These systems combine PLC, motion control, and robotics into a single architecture, simplifying operations and enhancing efficiency.

PC-based Control Technology

PC-based control technology is central to Beckhoff’s offerings. This approach leverages the power of industrial PCs to execute complex control algorithms, ensuring high performance and flexibility in production lines.

TwinCAT Automation Software

TwinCAT (The Windows Control and Automation Technology) is Beckhoff’s flagship software. It transforms any compatible PC into a real-time control system, facilitating seamless integration and communication across various production stages.

EtherCAT: High-speed Communication

EtherCAT (Ethernet for Control Automation Technology) is a high-performance communication protocol developed by Beckhoff. It enables rapid data exchange and synchronization, crucial for maintaining the precision required in tire manufacturing.

Modular I/O Systems

Beckhoff’s modular I/O systems offer scalable and flexible solutions for input and output needs. These systems support a wide range of sensors and actuators, enhancing the adaptability of production lines to different manufacturing requirements.

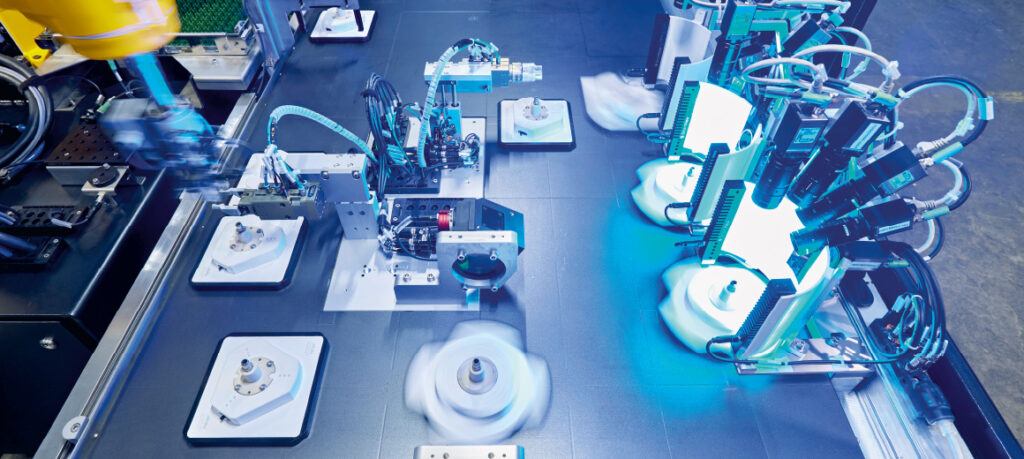

Enhancing Efficiency and Precision in Tire Manufacturing

Material Handling and Preparation

Efficient material handling is critical in tire production. Beckhoff’s automation solutions ensure precise material mixing and feeding, reducing waste and enhancing product quality.

Extrusion and Calendaring Processes

Automation in extrusion and calendaring processes ensures consistent material thickness and quality. Beckhoff’s control systems monitor and adjust parameters in real-time, maintaining optimal conditions throughout the production.

Tire Building Automation

In tire building, precision and repeatability are essential. Beckhoff’s automation technology ensures accurate placement of components, reducing defects and improving overall product consistency.

Curing and Vulcanization

The curing process is crucial for tire performance. Beckhoff’s systems provide precise temperature and pressure control, ensuring uniform curing and optimal tire properties.

Inspection and Quality Control

Automated inspection systems are vital for maintaining high-quality standards. Beckhoff’s vision systems and data analytics tools detect defects early, allowing for corrective actions before products reach the market.

Real-time Data and Analytics

Data Acquisition and Monitoring

Beckhoff’s automation solutions include comprehensive data acquisition and monitoring capabilities. Real-time data collection enables manufacturers to track production metrics and identify areas for improvement.

Predictive Maintenance

Predictive maintenance, powered by advanced analytics, helps in identifying potential equipment failures before they occur. Beckhoff’s systems analyze data trends to predict maintenance needs, reducing downtime and maintenance costs.

Sustainability and Energy Efficiency

Reducing Waste and Emissions

Automation plays a significant role in reducing waste and emissions in the tire and rubber industry. Beckhoff’s solutions optimize resource utilization and minimize waste, contributing to more sustainable manufacturing practices.

Energy-efficient Production

Beckhoff’s control systems are designed to enhance energy efficiency. By optimizing production processes and reducing idle times, these systems help lower energy consumption and operational costs.

Custom Solutions for Unique Needs

Tailored Automation Strategies

Beckhoff understands that each manufacturing facility has unique requirements. They offer tailored automation strategies that address specific challenges and optimize production processes accordingly.

Scalable Solutions

Scalability is a key feature of Beckhoff’s automation solutions. Whether for small-scale operations or large manufacturing plants, their systems can be scaled to meet evolving production demands.

Industry 4.0 and the Future of Tire Manufacturing

Smart Manufacturing

The integration of Industry 4.0 principles is transforming tire manufacturing into a smart, connected industry. Beckhoff’s automation solutions enable seamless connectivity and data exchange across the production chain.

IoT and Cloud Integration

The Internet of Things (IoT) and cloud computing are revolutionizing data management. Beckhoff’s systems facilitate IoT and cloud integration, providing real-time insights and improving decision-making processes.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are becoming integral to modern manufacturing. Beckhoff’s advanced analytics tools leverage AI and ML to enhance predictive maintenance, quality control, and process optimization.

Training and Support Services

Comprehensive Training Programs

Beckhoff offers comprehensive training programs to ensure that manufacturing personnel are well-versed in using their automation solutions. These programs cover installation, operation, and maintenance.

Technical Support

Robust technical support is crucial for minimizing downtime. Beckhoff provides 24/7 technical support services, ensuring that any issues are promptly addressed to keep production running smoothly.

Successful Implementations

Numerous tire manufacturers have successfully implemented Beckhoff’s automation solutions. These case studies highlight the tangible benefits, including increased efficiency, improved product quality, and reduced operational costs.

Customer Testimonials

Customer testimonials provide insights into the real-world impact of Beckhoff’s automation technology. Positive feedback from industry leaders underscores the value and reliability of these solutions.

Beckhoff’s advanced automation solutions are revolutionizing the tire and rubber industry. By integrating cutting-edge technology, they enhance efficiency, precision, and sustainability in manufacturing processes. As the industry continues to evolve, Beckhoff remains at the forefront, driving innovation and excellence in tire production.